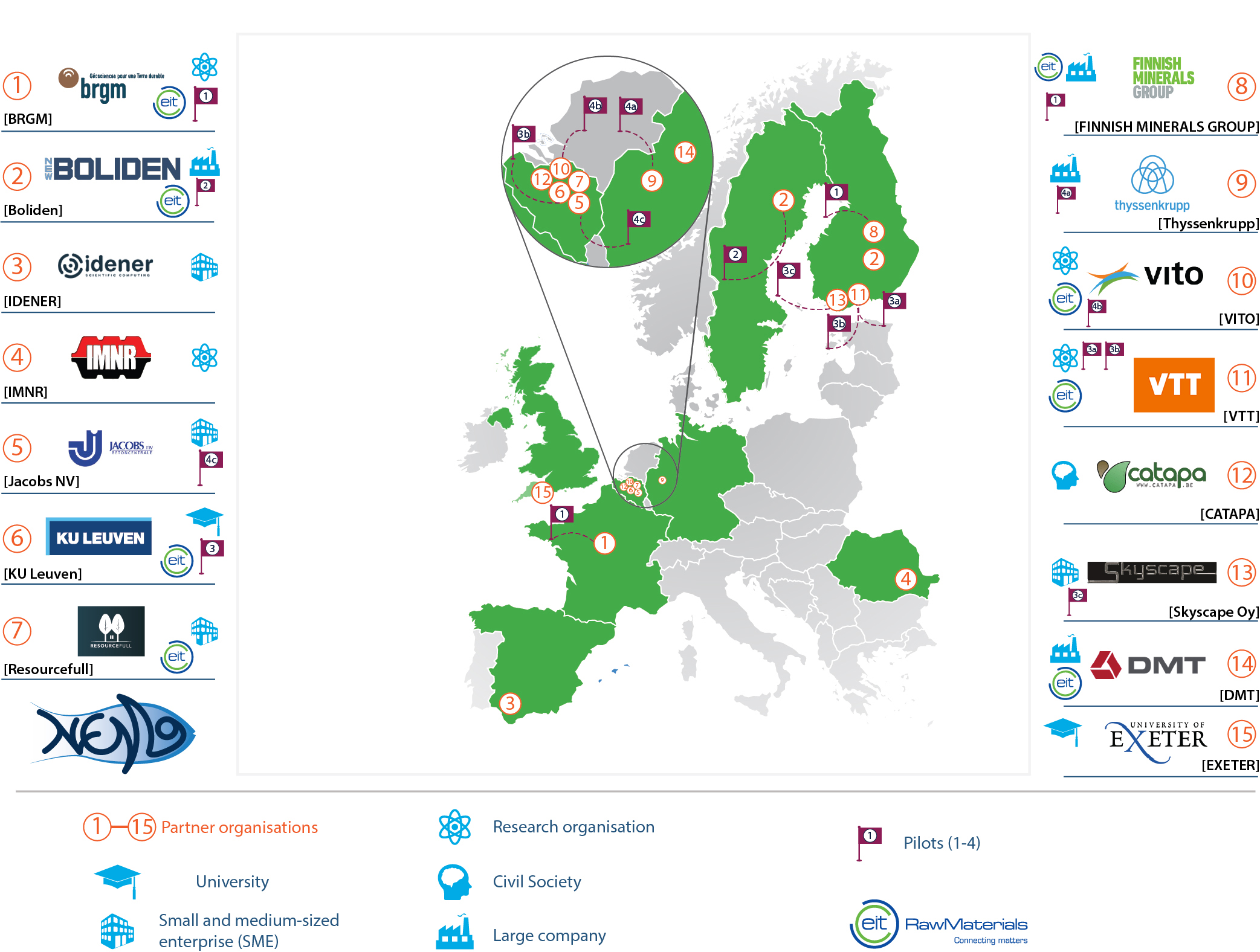

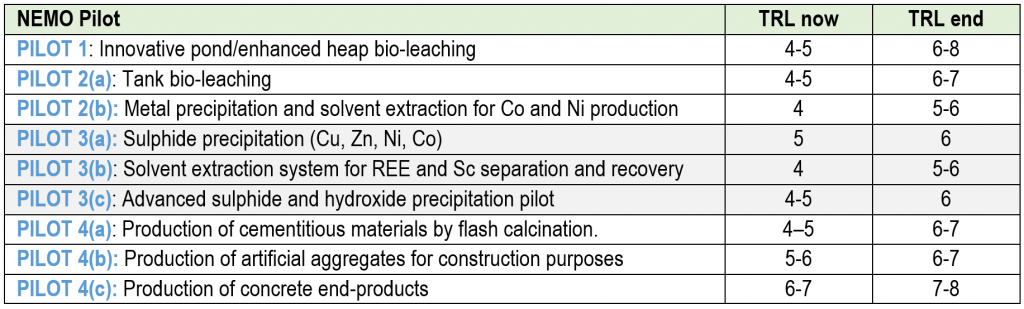

A key aspect of the NEMO project is to increase the technology readiness level (TRL) of different innovative technologies within the near-zero waste treatment of sulphidic ores and sulphidic mining waste. For this, different NEMO pilots are set-up around the E.U., as is indicated by the purple flags in the figure below.

The TRL at the start of NEMO and the TRL aimed for at the end of the NEMO project is indicated in the Table below.

More info of the pilots is given in the paragraphs below.

Pilot 1: Innovative pond/ enhanced heap bio-leaching

In pilot 1 ‘innovative pond/ enhanced heap bio-leaching’, the partners Terrafame/Finnish Minerals Group, Exeter and BRGM work on innovative bio-leaching pilots for metal extraction. Pilot 1 will have as input material the sulphidic, low-grade primary heap residue from the Sotkamo mine (Finland). Bioleaching composes either heap-leaching or leaching in “ponds”. The pond leaching design relies on special agitators and aerators, which makes operations in low-tech reactors possible, but with extremely high pulp densities and without a typical decrease in the leaching efficiency.

Discover more of the sub-pilots:

Pilot 2: Tank bio-leaching

In pilot 2, tank bioleaching is combined with different metal precipitation and purification steps to produce Co, Ni, Cu and Zn. The pilot is used to treat high-pyrite containing residues. The core process in the pilot is a tank bioleaching process, developed by BOLIDEN, VTT and BRGM. Metals are recovered by precipitation as either mixed Co-Ni-Cu-Zn concentrate or (Co-Ni)S, CuS and ZnS. The Co-Ni mixture is further processed to produce battery grade CoSO4 and NiSO4 by KU Leuven and VTT. Arsenic is removed during the Fe-hydroxide precipitation and the final gypsum precipitate is reprocessed to produce CaO. As an alternative to the bioleaching, the concept of alkaline autoclave leaching is tested by IMNR.

Discover more of the sub-pilots:

- Tank bioleaching (Boliden)

- Metal purification to battery grade sulphides (VTT)

- Metal purification to battery grade sulphides (KUL)

- Alkaline pressure leaching (IMNR)

Pilot 3: Additional metal recovery

In pilot 3 different processes for metal recovery from pregnant leach solution from sulphidic ores/residues are upscaled. There are three principal activities in PILOT 3: VTT’s sulphide precipitation pilot for precipitation of CuS, ZnS and (Co-Ni)S, an aqueous (VTT) and a non-aqueous (KUL) solvent extraction mixer-settler battery system for Sc and REE recovery, and a hydroxide precipitation pilot for additional metal recovery (skyscape).

Discover more of the sub-pilots:

- Sulphide precipitation (Cu, Zn, Ni, Co) (VTT)

- Solvent extraction system for REE and Sc separation and recovery (VTT)

- Solvent extraction system for REE and Sc separation and recovery (KUL)

- Advanced sulphide and hydroxide precipitation pilot (Skyscape)

Pilot 4: Cleaned Mineral Fraction Upcycling to Cement and Concrete End Products

In pilot 4, NEMO partners Thyssenkrupp, Jacobs NV, Resourcefull and VITO work together on the production of construction materials incorporating mining waste. The three main actions as part of this pilot are the production of alternative composite cements, aggregates and concrete end-products.

Discover more of the sub-pilots:

- Production of cementitious materials by flash calcination (Thyssenkrupp)

- Production of artificial aggregates for construction purposes (VITO)

- Production of concrete end-products (Resourcefull)

- Production of concrete end-products (Jacobs)