- Responsible partner: KU Leuven

- Location of pilot: KU Leuven, Leuven, Belgium

- TRL 5

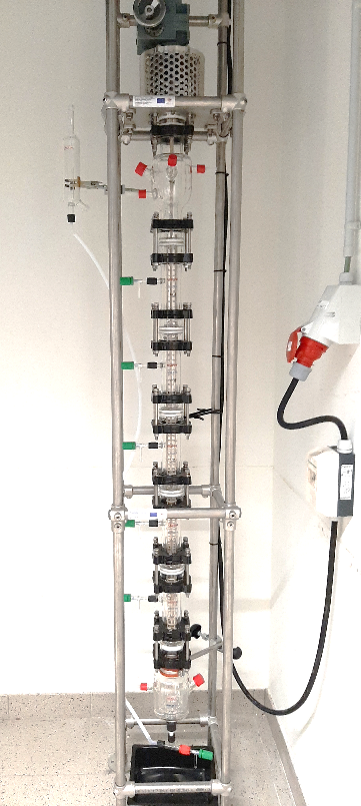

The pilot ‘Metal purification to battery grade sulphides’ focuses on the dissolution of hydroxide metal precipitates followed by solvent extraction and crystallization for the production of ultra-pure battery-grade metal sulfates (CoSO4, NiSO4). The pilot consists of a leaching reactor, a battery of mixer-settlers (SX Kinetics, max. 20 stages) or, alternatively, an agitated column SX setup (Sulzer). The leaching reactor was designed and constructed in collaboration with HiTec Zang, and consists of two heatable glass mixing reactor chambers of size 1 L and 5 L, both coupled to a heatable glass filtration unit. The mixer-settler battery was designed and constructed by SX Kinetics, with peristaltic pumps supplied by Cole-Parmer. The mixing and settling chambers are both constructed of glass, with a volume of 270 mL and 1000 mL, respectively. The stages are connected counter-currently with polymeric tubing. The flow of organic and aqueous solutions through the mixer-settlers is controlled by the peristaltic pumps, with flow rates up to 10 L/h. Only room temperature experiments are possible. The agitated column is of the Kühni ECR 32 column from Sulzer. This agitated column is useful when a high number of stages is required for the separation. It also has the advantage that it allows to work easily with almost any O/A ratio. The active height and volume is about 1.2 m and 0.9 L, respectively. It is entirely jacketed to be heated or cooled by a liquid medium and its height can be adapted by adding or removing sections. By varying the active volume, the column can be used with a total flow range of 5-25 L/h.

|

|

From left to right: Leaching reactor, agitated column.

Contact

Solvomet Group https://solvomet.eu/contact/