- Responsible partner: Thyssenkrupp

- Location of pilot: Thyssenkrupp research center, Beckum (Germany)

- TRL: 4-6-8

The pilot ‘Production of cementitious materials by flash calcination’ is part of the Thyssenkrupp research center. There are three sizes of flash calciner:

- Lab scale

- Pilot scale

- Semi-industrial scale

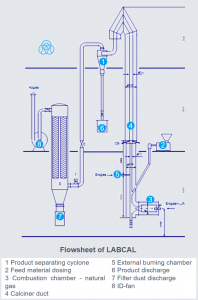

Lab scale flash calciner

The ‘Lab scale flash calcination’ (LABCAL) test facility was put back into operation especially for the NEMO project. Like the other flash calciners located at the research centre of thyssenkrupp the LABCAL (TRL4) can be used for thermal treatment of material (-2mm) in heated gas suspension from 600°C to 1200°C.

The pilot has the following chemical, mineralogical and physical properties:

Changing chemical properties:

- Calcining (decarbonization) e.g. of limestone, phosphate ore, magnesite

Changing mineralogical properties:

- Dehydroxilation of clay minerals (Kaolinite, Illite)

- Volatilize of crystal water e.g. of nickel ore

- Conversion of gypsum from flue gas desulfurization to anhydrite

Changing physical properties:

- Magnetic roasting of iron ore by changing the mineral structure: Oxidization from hematite to magnetite

The LABCAL pilot characteristics‘ are as follows:

- lab scale flash calciner without pre-heater

- natural gas firing

- nominal throughput: 5-10 kg/h

- temperature range 600…1200 °C

- retention time ~1 s

- particle size 0…3 mm

- oxidizing and reducing calciner atmosphere

- Gas velocities: 14–20 m/s

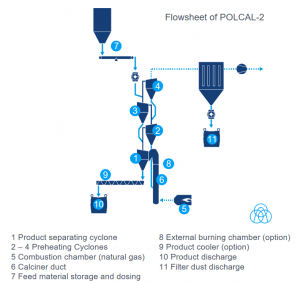

Pilot scale flash calciner

The pilot scale flash calciner (POLCAL-2) operates at TRL6 and can be used for thermal treatment of different materials e.g. calcination of carbonic materials (limestone, dolomite, phosphate ore) or activation of clays (kaolin, illite, etc.) or dehydroxilation of metal ores (iron, nickel, titanium, etc.).

The POLCAL-2 characteristics’ are as follows:

- pilot scale flash calciner with three-stage pre-heater

- natural gas firing

- nominal throughput: 30-80 kg/h

- temperature range 600…1200 °C

- retention time 1-2 s

- particle size 0…3 mm

- oxidizing and reducing calciner atmosphere

- Gas velocities: 14–20 m/s

Pilot scale flash calcination

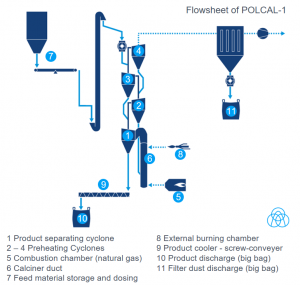

Semi industrial scale flash calciner

The semi industrial scale flash calciner (POLCAL-1) operates at TRL8. Just like the POLCAL-2, it can be used for thermal treatment of different materials e.g. calcination of carbonic materials (limestone, dolomite, phosphate ore) or activation of clays (kaolin, illite, etc.) or dehydroxilation of metal ores (iron, nickel, titanium, etc.).

The POLCAL-1 characteristics’ are as follows:

- pilot scale flash calciner with three-stage pre-heater

- natural gas firing

- nominal throughput: 200…500 kg/h

- temperature range 500…1200 °C

- retention time 1-2 s

- particle size 0…3 mm

- oxidizing and reducing calciner atmosphere

- Gas velocities: 14–20 m/s

Semi industrial scale flash calcination

Contact

Andreas Hoppe (T: +49 2525 99-3142 | andreas.hoppe-at-thyssenkrupp.com)

Jost Lemke (T: +49 2525 99-3915 | jost.lemke-at-thyssenkrupp.com)

Thyssenkrupp Industrial Solutions AG,

Graf-Galen-Str. 17

59269 Beckum, Germany

www.thyssenkrupp-industrialsolutions.com/en/industries/cement