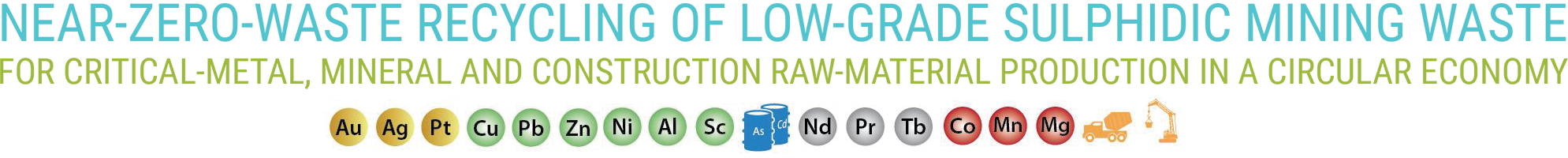

Figure 1 The dissolution pilot at KU Leuven consisting of a 1 L and 5 L jacketed reactor and filtration units.

As part of the H2020 NEMO project “Near-zero-waste recycling of low-grade sulphidic mining waste for critical-metal, mineral and construction raw-material production in a circular economy’’, KU Leuven has developed a solvometallurgical process for the separation of rare-earth elements (REEs), as part of the WP3 pilot. The REE concentrate, originally obtained by precipitation from the scrub raffinate in the VTT Pilot 3a, was mainly rich in the heavier REEs, i.e. the elements dysprosium up to lutetium, including yttrium. KU Leuven targets to separate these elements into a ‘lighter’ and ‘heavier’ group, and to purify erbium. The latter element is crucial to modern-day telecommunication, as it is used to amplify signals in optical glass-fibre cables, keeping the world constantly connected.

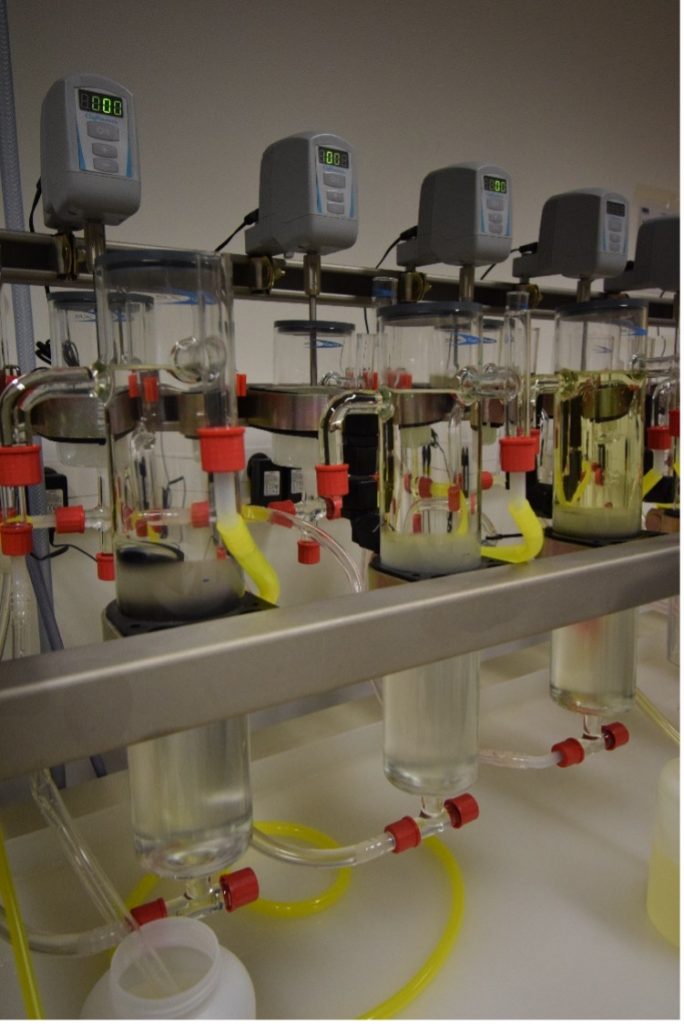

Figure 2 The KU Leuven mixer-settler pilot, processing the feed solution obtained at the dissolution pilot, to remove transition metal impurities.

The KU Leuven dissolution and solvent extraction pilots (Figures 1 and 2, respectively), started up in June 2021 and are located at the SOLVOMET Group labs, KU Leuven department of Chemistry. 60 litres of feed solution are already purified and are to be further processed by the same set-up to separate the rare-earths. The pilot is expected to run until the end of September 2021, and will be the first of its kind to separate contiguous rare earths making use of non-aqueous solvent extraction.

(Brecht Dewulf, Leuven, 06.07.2021)