Responsible partner: BRGM

Location of pilot: Orleans, France

TRL: 6-7

The aim of the bioleaching pilot is to develop and to optimise technologies that enhance bioleaching processes and the recycling and re-use of metal-containing waste with a view to developing a circular economy and minimising environmental impacts in the extraction of non-renewable resources.

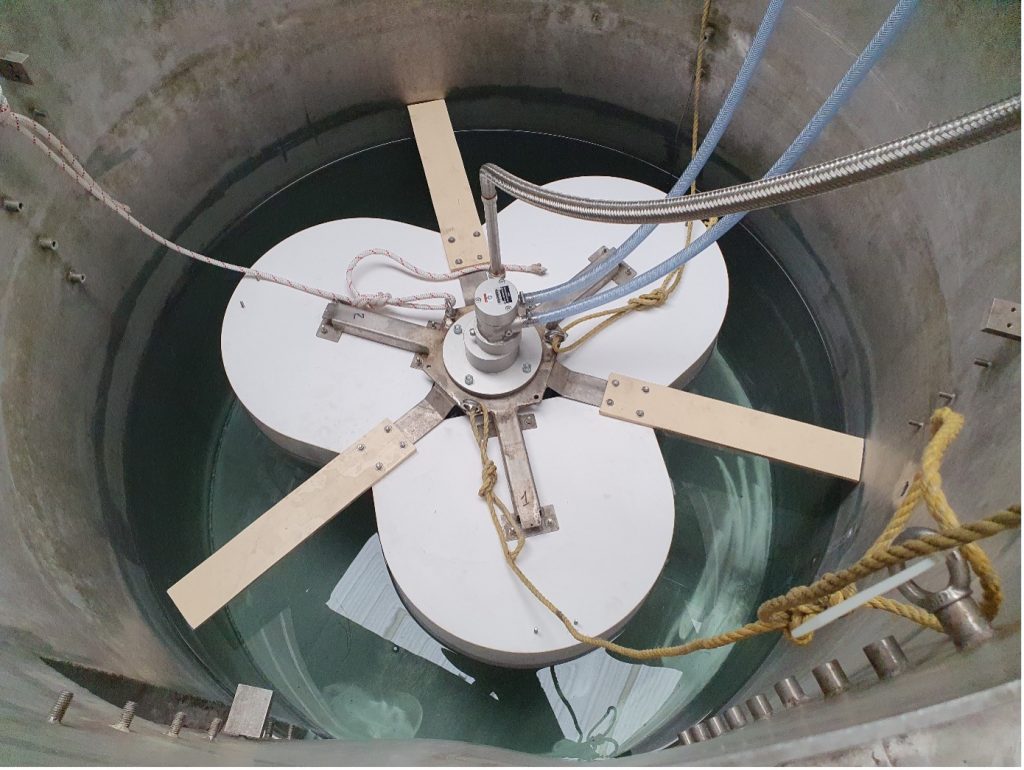

The bioleaching pilot of BRGM comprises two separate units: a 110-L continuous stirred tank reactor (CSTR) series and a 1.8-m3 batch reactor equipped with a floating agitator. The CSTR series is composed of a primary 50-L reactor and three secondary 20-L reactors that can be operated individually, in series or in parallel and the pulp transfer between the reactors is done by overflow. An upstream 150-L agitated reactor can be used to prepare the feeding pulp of the CSTR.

All reactors are equipped with aeration and temperature control systems, as well as an automatic control pumping system for feeding (ore pulp, nutrient solutions, acid and/or calcite). Gas inlet can be chosen among four different gasses, i.e., air, oxygen, nitrogen and carbon dioxide, or a mixture of them.

The pilot can treat primary and secondary ores, as well as different types of metal-containing waste, such as e-waste.

The main tasks covered by pilot operations include:

· Selection and enhancement of bioleaching microbial consortia

· Understanding of mechanisms and limiting steps affecting the bioleaching process

· Optimization of operating conditions, such as agitation speed, impeller type and configuration, gas flow, solid load, temperature and pH at different scales.

· Upscaling of bioleaching processes from laboratory to pilot scale.

· Technology transfer for industrial applications

In addition to the pilot reactors, BRGM has the equipment (and expertise) to perform diverse sample pre-treatments such as drying, coarse and fine grinding, sieving and sample splitting for samples in solid or pulp form in amounts ranging from lab scale (grams) to pilot scale (several tonnes). Moreover, after pilot operation, post-treatment of bioleached pulp using filter press is possible for solid liquid-separation.

110-L CSTR bioleaching pilot

1.8-m3 batch reactor

1.8-m3 batch reactor

Floating agitator for the 1.8-m3 bioreactor

Contact data:

Douglas PINO HERRERA / d.pinoherrera@brgm.fr

Anne-Gwénaëlle Guezennec /a.guezennec@brgm.fr

For further information, you can visit www.brgm.eu